CRANKSHAFT MACHINES

MACHINES FOR COMMERCIAL/PASSENGER VEHICLE CRANKSHAFT MACHINING UH-SERIES

The UH series stands for highest productivity in the mass production of large crankshafts and other rotary workpieces. The modularly designed machines are characterized by high stability and precision accuracy as well as consistent quality with maximum availability. The UH series can also be used for machining other rotary workpieces such as camshafts, connecting rods and common rails of passenger car, commercial vehicle and large industrial engines.

DESCRIPTION

The machine is designed as a complete solution for machining of large crankshafts for commercial and passenger cars and can be equipped with two spindles on each side, allowing simultaneous machining for bouth sides.

The UH series is available in the following versions:

- 1 spindle

- 1+1 spindle

- 2 spindle

- 2+2 spindle

TECHNICAL DATA

| Machining unit | X-Axis | mm | 2500 |

| Y-Axis | mm | 630 | |

| Z-Axis | mm | 800 | |

| Rapid traverse | m/min | 40 | |

| Acceleration | m/sec² | 2,7 | |

| Torque | Nm | 10 | |

| Swivel spindle | Type of coupling | HSK | 63 |

| Bearing | φ | 63 | |

| max. RPM | U/min | 8.000 | |

| max. Torque | Nm | 70 | |

| Self regulated pump | Quantity | l/min | 0,5 |

| Tank volume | l | 6 | |

| Workpiece | Length | mm | 1200 |

| Diameter | mm | 240 | |

| Controls | Siemens 840D/Indramat MTC200 | ||

| Machine data | Length | mm | 6.800 |

| Width | mm | 5.984 | |

| Height | mm | 4.400 | |

| Weight | kg | 21.000 | |

| Technical data may vary due to customers specific needs. | |||

APPLICABILITY

- Crosscutting and cantering

- Deep drilling of oil holes

- Weight reduction drilling

- End face machining

WORKPIECES

MACHIES FOR PASSENGER VEHICLE CRANKSHAFT MACHINING AF-SERIES

Special purpose machine designed for medium or large scale production. Primarily focused on crankshaft processing and designed to be easily implemented into production lines.

DESCRIPTION

3-axis unit with work tool revolvers and a NC swivel table allows the machine to simultaneously process two workpieces able to be used in an array of deferent machining processes. With its modular design the AF series can be easily implemented into production lines.

TECHNICAL DATA

| Machining unit | X-Axis | mm | 200 |

| Y-Axis | mm | 400 | |

| Z-Axis | mm | 630 | |

| Rapid traverse | m/min | 40 | |

| Acceleration | m/sec² | 2,4 | |

| Torque | Nm | 2x13 | |

| Swivel unit | Type of coupling | HSK | 63 |

| Bearing | φ | 63 | |

| max. RPM | U/min | 8.000 | |

| max. Torque | Nm | 60 | |

| Self regulated pump | Quantity | l/min | 0,5 |

| Tank volume | l | 6 | |

| Workpiece | Length | mm | 280 |

| Weight | kg | 10 | |

| Controls | Siemens 840D/Indramat MTC200 | ||

| Machine data | Length | mm | 5.500 |

| Width | mm | 2.000 | |

| Height | mm | 2.200 | |

| Weight | kg | 7.000 | |

| Technical data may vary due to customers specific needs. | |||

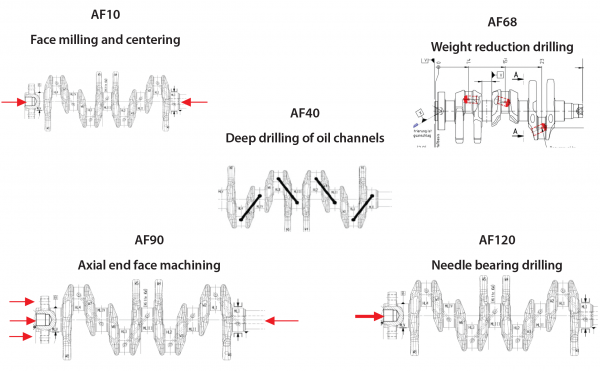

APPLICABILITY

The AF series is designed for the following machining operations:

- Face milling and cantering

- Deep drilling of oil channels

- Weight reduction drilling

- Axial end face machining

- Needle bearing drilling

ADVANTAGES

- Stable process

- High productivity with multi-spindle processing

- Lower maintenance costs

- Adaptability to customers used drilling technology

- Shorter delivery time

WORKPIECES