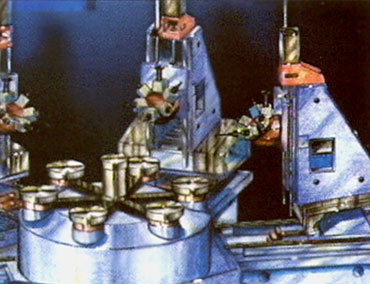

Presentation of the machine concept

Next to central rotary NC table, that can be additionally equipped with NC planets (2 to 8 planets), there are laterally placed 1-3 axis CNC workstations that can be the holders of different processing spindles:

|

With adaptation to workpiece we guarantee an optimal solution, and with the use of modern cutting tools and the shortest possible tact time.

With the integration of standard drive elements by renowned manufacturers we achieve the following characteristics of workstations:

| Pace of axis X | 400 mm |

| Pace of axis Y | do 1200 mm |

| Pace of axis Z | 600 mm |

| Speed of movement | 60 m/min |

| Axis accelerations | 6m/s2 |

| Spindle revolutions | Up to 12000 revolutions/min |

| Tool switch | 3,0 sec (9000 rev/min - 0 - 9000 rev/min) |

| Tool holder | HSK 63 or HSK 100 |

Entire machine is controlled with a program system type SIEMENS (840 D) or INDRAMAT (MTX). Machine loading is at a customer’s choice and can be implemented manually, with manipulator or in most cases with automatic input –robot.

Implementation of the machine is adapted for work in dry/MMS system or for processing with cooling emulsion.

Use of module construction enables relatively fast and simple conversion on various work pieces.